Backpressure, caused by issues like faulty mufflers or restricted converters, negatively affects speed, torque, fuel consumption, and emissions in single exhaust systems. To prevent buildup, maintain smooth airflow with clean filters, inspect for leaks/obstructions, upgrade intake components, and regularly replace worn parts. Balancing these strategies ensures optimal performance and efficiency in single exhaust systems.

Backpressure in a single exhaust system can cause significant issues, leading to reduced performance and potential damage. This guide delves into the root causes of backpressure and its detrimental effects on these systems. We offer practical strategies to prevent buildup, ensuring optimal efficiency. Additionally, maintenance tips are provided to help you keep your single exhaust system running smoothly. By implementing these measures, you’ll minimize risks and maintain a seamless, effective exhaust setup.

- Understanding Backpressure and Its Effects on Single Exhaust Systems

- Strategies to Prevent Backpressure Buildup

- Maintenance Tips for Efficient Single Exhaust Operation

Understanding Backpressure and Its Effects on Single Exhaust Systems

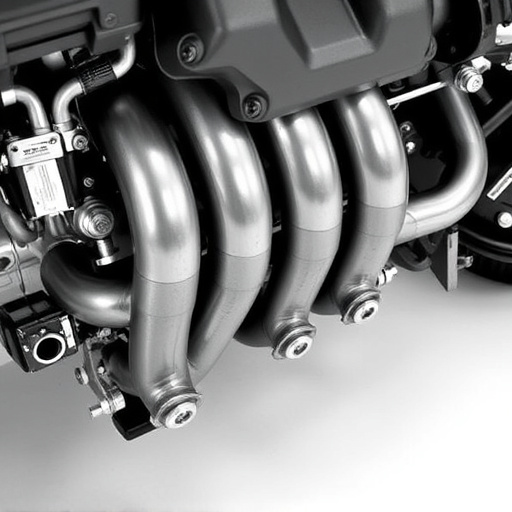

Backpressure is a common issue that can significantly affect the performance and efficiency of a single exhaust system. In simple terms, it refers to the resistance against the flow of gases, primarily caused by restrictions within the exhaust path. When backpressure builds up, it hinders the smooth passage of exhaust gases from the engine, leading to reduced power output and potential damage to the internal combustion chamber. This is particularly critical in single exhaust systems, where all exhaust gases are directed through a single pipe, amplifying the impact of any blockages or bottlenecks.

Understanding backpressure involves recognizing its various causes, such as faulty mufflers, restricted catalytic converters, or even improper tuning. The effects can range from decreased engine speed and torque to increased fuel consumption and potential environmental concerns. To maintain optimal performance, it’s essential to address these issues proactively, especially when upgrading with high-flow performance exhaust systems or installing coilover kits that might alter the vehicle’s dynamics. Regular maintenance and ensuring proper fitment of intake components are key strategies to mitigate backpressure and keep single exhaust systems running smoothly.

Strategies to Prevent Backpressure Buildup

To prevent backpressure buildup in a single exhaust system, several proactive strategies can be implemented. Firstly, focus on ensuring smooth airflow by maintaining clean and high-performance air filters. Regularly replacing these filters allows for unobstructed air flow into the engine, thereby reducing resistance that could lead to backpressure. Additionally, examining and upgrading intake components can significantly enhance airflow; this includes checking for any leaks or obstructions which might restrict air entry.

Moreover, proper maintenance of exhaust system parts, such as brake rotors (which play a minor role in airflow but are crucial for overall engine health), is vital. Regular inspection and replacement of worn-out components ensure the exhaust system operates efficiently, minimizing delays that could cause backpressure. Balancing these strategies helps maintain optimal performance within the single exhaust system, preventing issues related to backpressure buildup.

Maintenance Tips for Efficient Single Exhaust Operation

To maintain a single exhaust system’s efficiency and prevent backpressure issues, regular upkeep is crucial. Start by ensuring that the exhaust components, including headers, pipes, and the muffler, are free from any obstructions or damage. Regular cleaning and inspection of these parts can help identify potential issues early on. Additionally, checking and replacing worn-out parts such as gaskets, seals, and suspension kits is essential to maintain optimal airflow.

Another key aspect is proper alignment and condition of the exhaust system components. Misaligned pipes or damaged sections can disrupt the flow of gases, leading to backpressure. Regularly inspect for any loose connections and ensure that all bolts and brackets are securely fastened. Upgrading muffler tips with high-performance alternatives can also enhance exhaust flow, reducing backpressure and improving overall engine performance.

By understanding backpressure, implementing preventive strategies, and adhering to regular maintenance practices, you can significantly reduce the occurrence of backpressure issues in your single exhaust system. These measures ensure optimal performance, efficiency, and longevity of the system, providing a smoother and more reliable operation for various applications. Remember that proactive care is key to avoiding costly repairs and ensuring your single exhaust system runs smoothly.